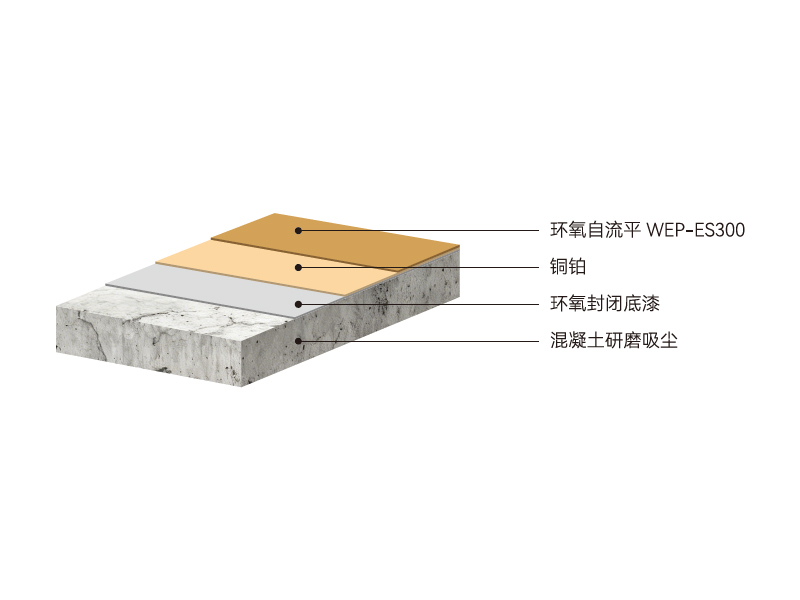

WEP-ES300 (Anti-static Grade)

Applicable Scenarios:

Electronic clean room, semiconductor factory, data center, precision instrument workshop, chemical explosion-proof area, operating room

Coating Thickness: 2-3mm

Core Features:

Electrostatic dissipation type, surface resistance 10⁶-10⁹Ω, environmentally friendly and odorless, suitable for precision electronics / explosion-proof scenarios

Key Technical Parameters:

Compressive strength ≥ 45MPa, tensile strength ≥ 10MPa, system grounding resistance ≤ 10Ω, no abnormalities after exposure to 20% acid and alkali for 60 hours

surface effect:

The seamless, smooth, and easy-to-clean coating achieves electrostatic dissipation by constructing a conductive coating + copper foil network

Cases

Cases

cn

cn