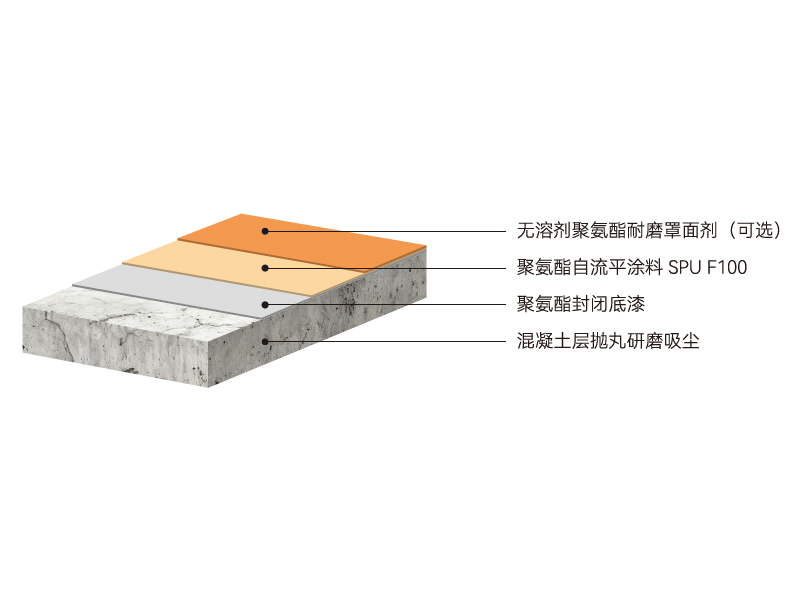

SPU F100 (General Purpose Grade)

Applicable Scenarios:

Manufacturing purification workshops, laboratories, chemical and pharmaceutical workshops, warehouse passageways, hospital corridors, garages

Coating Thickness: 1.5-2.5mm

Core Features:

Seamless integration, easy to clean and maintain, elastic to bridge fine cracks, wear-resistant, suitable for medium to heavy loads

Key Technical Parameters:

Compressive strength ≥ 60MPa, tensile strength ≥ 18MPa, wear resistance ≤ 20mg, temperature resistance -30℃ to 80℃, dustproof level ≥ Level 6

surface effect:

Single-layer, seamless overall, smooth and matte finish

Cases

Cases

cn

cn