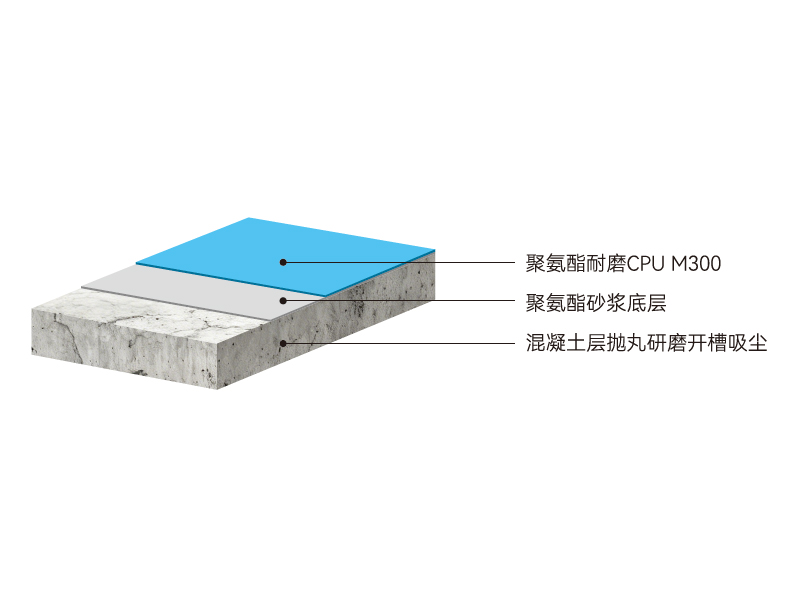

CPU M300 (Wear-Resistant Type)

Applicable Scenarios:

Food, beverage, beer, laboratory, clean workshop, canteen, tobacco, packaging workshop, new energy, pharmaceutical packaging workshop

Coating Thickness: 1.5-2.5mm

Core Features:

High wear resistance, moderate load resistance, bio-based environmental protection, FDA food hygiene standards

Key Technical Parameters:

Compressive strength ≥ 65MPa, tensile strength ≥ 12MPa, wear resistance ≤ 13mg, resistance to 30% acid and alkali for 72 hours without abnormality, adhesion ≥ 3.8MPa

surface effect:

Single-layer, seamless, smooth and matte

Cases

Cases

cn

cn