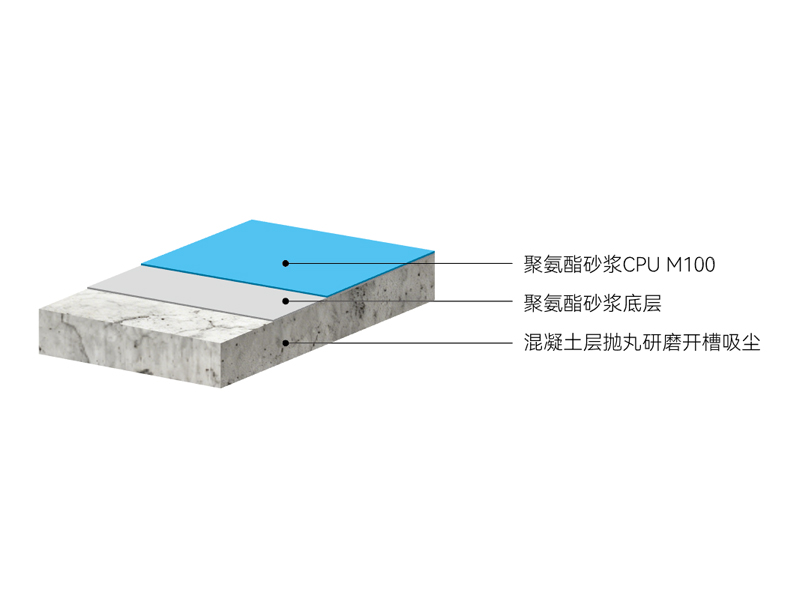

CPU M100 (General Purpose Type)

Applicable Scenarios:

Central kitchen, dairy workshop, cold storage (0℃ to -40℃), meat processing, new energy, pharmaceutical packaging workshop

Coating Thickness: 4-6mm

Core Features:

Resistant to -40℃ freeze-thaw cycles and 120℃ steam cleaning, FDA certified, addressing the issues of "low-temperature brittleness and high-temperature softening" in traditional epoxy

Key Technical Parameters:

Compressive strength ≥ 60MPa, tensile strength ≥ 10MPa, wear resistance ≤ 15mg, anti-slip coefficient ≥ 0.6 (R10 grade), surface dryness ≤ 6h / full dryness ≤ 24h

surface effect:

Surface effect: Single-layer seamless, smooth and matte finish.

Cases

Cases

cn

cn