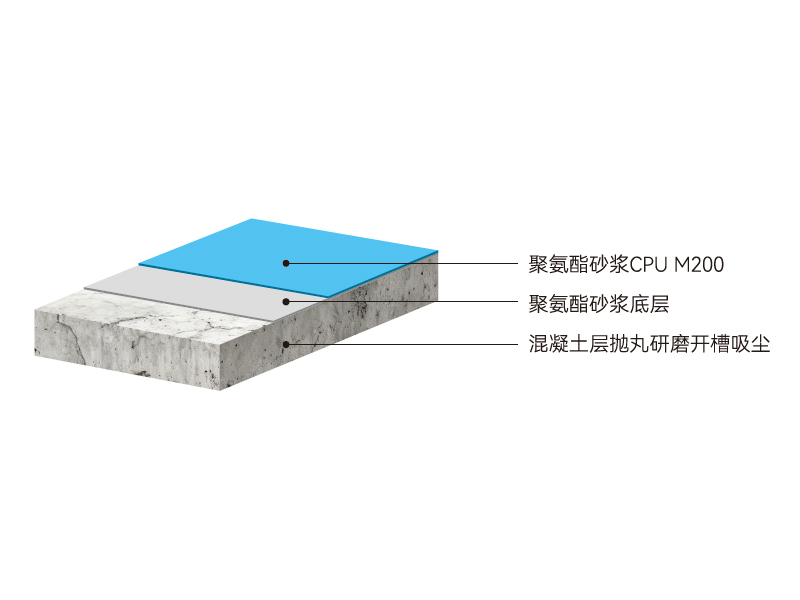

CPU M200 (Thin-Type)

Applicable Scenarios:

Electronics, new energy, clean room, tobacco, pharmaceutical packaging, laboratory, office space, and conference hall (light load + high cleanliness)

Coating Thickness: 1-1.5mm

Core Features:

Bio-based materials: eco-friendly & low-carbon, low VOC, temperature-resistant, supports Pantone/GB color card customization

Key Technical Parameters:

Compressive strength ≥ 65MPa, tensile strength ≥ 12MPa, temperature resistance -40℃ to 130℃, wear resistance ≤ 15mg, adhesion ≥ 3.5MPa

surface effect:

Monolayer, integral & seamless, smooth matte finish, supports customized colors (China Building Color Card, Pantone Color Card)

Cases

Cases

cn

cn